Soldering iron tip care and maintenance (2023)

If the soldering iron is not properly maintained that can make soldering a challenging task. A well-maintained tip ensures a reliable connection between the components and prevents damage to the circuit board.

The maintenance of the soldering iron tip not only increases its lifespan but also makes the soldering iron perform well. The tips that can help you to maintain your soldering tip are to clean your iron tip before and after every use, tin the tip, store the soldering iron properly, replace the tip if needed, avoid overheating of the tip, and use the right solder.

This article will provide you with details about soldering iron tip care and maintenance. Also, what are the tips that can keep your tip safe?

Let’s get started

Soldering iron tip care & maintenance

Whether you have used soldering irons before or not, you are aware that the tip is the most essential component. Taking care of the soldering iron tip is simple, but you need to know how to take care of the iron tip.

First, we have to know what are the factors that make the tip of soldering iron worst.

Factors that make the soldering iron tip bad

There are a lot of factors that can make the soldering iron tip bad. Before going into detail about the tips let’s first discuss the factors that make the tip poor.

1. Oxidation

When you don’t clean the tip after use that can lead to severe oxidation on the tip. The tip can be oxidized quickly when exposed to air, especially if it is left unused for a long period.

The iron’s capacity to conduct heat is diminished by the layer of dark, dull, and crusty material that is produced by oxidation. Proper cleaning and maintenance can keep the soldering iron tip safe from oxidation.

2. Contamination

Contamination of soldering iron refers to the substances such as flux, solder and other debris on the surface of the tip. Lack of cleaning or ineffective cleaning methods might lead to contamination.

Contamination of soldering iron tips can have several consequences. There will be poor heat transfer to the joints and it can reduce the tip lifespan. The contaminated tip can produce weak and unclear joints.

3. Corrosion

The gradual breakdown of the metal surface due to the chemical reactions with acidic flux and improper maintenance is referred to as corrosion. On the surface of the tip, corrosion can cause pitting, discoloration, and other outward indications of deterioration.

This will also affect the overall performance of the soldering iron and make the soldering difficult. This can also increase the risk of damage to the components being soldered. To prevent corrosion, it is essential to use the appropriate type of flux and take the important steps to clean the soldering iron tip.

4. Overheating

Overheating also damages the tip of the soldering iron with time. If your soldering iron is creating joints at high temperatures constantly this can deteriorate the tip of the iron.

Try to work with soldering iron from time to time and set the temperature that is recommended. Also, don’t leave the soldering iron in on state. This will not only save the iron’s tip but will also increase the lifespan of a device.

Tips for care and maintaining soldering iron tip

A long-lasting, effective, and high-quality soldering experience depends on maintaining the soldering iron tip. We’ll now talk about how to take care of and maintain soldering iron tips.

1. Clean the tip

The soldering iron is susceptible to oxidation which can cause the tip to corrode and deteriorate. If you don’t clean the soldering iron after every use the issue can become severe.

To prevent this, you should regularly clean your soldering iron tip after every use. You can use a damp sponge or a brass sponge to clean the tip.

If the dirt is intense you should also use sandpaper, steel wool, or wire brushes but be careful while using these materials.

Cleaning the tip is a simple tip but very important if you want to take care of your soldering iron tip and don’t want to damage it.

2. Tin the tip

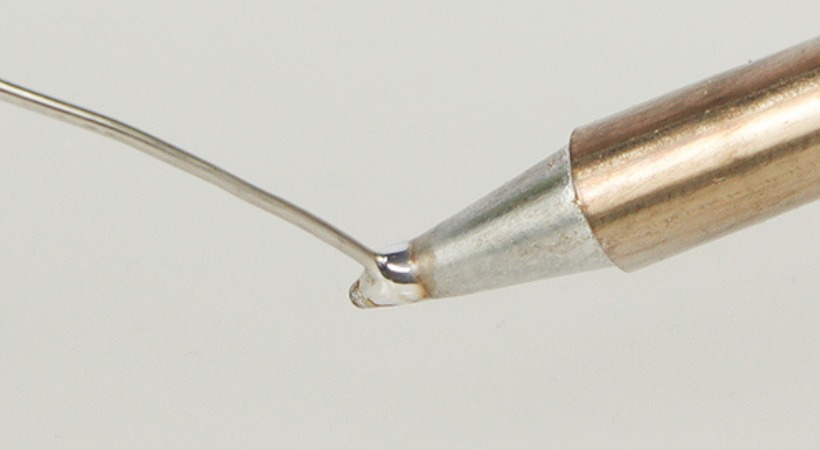

Tinning the tip of the soldering iron is an essential step. When we cover the tip with a thin layer of solder, we call tinning the tip.

Tinning the tip helps protect it from oxidation and prevents it from deteriorating.

To tin the tip, heat the soldering iron and apply a small amount of solder to the tip. Make sure to wipe away any excess solder with a damp sponge.

To maintain and improve the performance of the tip of the soldering iron tin the tip.

3. Store the soldering iron properly

Storing your soldering iron correctly is essential to protect the tip from damage. Sometimes we don’t store the soldering iron properly this also makes the condition worse and makes the iron rusted and corroded.

We store the soldering iron in a damp environment, and sometimes we don’t use them for long periods. This insensitive approach towards soldering iron can make its tip rusted, and oxidized, and make it of no use.

You should store the soldering iron in a dry and clean place, away from moisture, dust, and other contaminants. It is also a good idea to use a protective cap or cover to protect the tip from damage.

4. Replace the tip

Even with proper care and maintenance sometimes the tip of the soldering iron can wear out and will be damaged. The replacement of the tip is also one of the steps of maintenance.

The poor tip affects the performance of the soldering iron. Signs that your tip needs replacement include poor heat transfer, excessive corrosion, and reduced soldering efficiency.

You should replace the tip immediately if it shows any signs of damage or wear and tear.

5. Avoid overheating the tip

Overheating the tip can cause it to deteriorate faster and reduce its lifespan. Leaving the soldering iron on for an extended time without any use will overheat the tip.

Overheating can make the tip sensitive and can easily break down. You should also avoid applying excessive pressure on the tip while using it at a high temperature because it can affect and damage the tip.

To avoid and maintain a reasonable temperature is also a tip for keeping the soldering iron in good condition.

6. Use the Right Solder

Using the right type of solder is key for successful solder joints and for the tip of iron. It will maintain the quality and lifespan of your soldering iron tip. Lead-free and lead-based solders are used for soldering. Both of them have their pros and cons.

The lead-free required a high temperature for melting as compared to lead-based solder. So choose the solder that is compatible with a soldering iron.

Conclusion

Caring for and maintaining your soldering iron tip is crucial for achieving high-quality and long-lasting soldering results.

Some factors like oxidation, contamination, and overheating affect the tip of the soldering iron and also degrade its performance. Not cleaning the iron after use makes the situation of tip worse.

Remember to clean the tip after every use, tin the tip, store the soldering iron properly, replace the tip when necessary, avoid overheating the tip, and use the right solder. Taking the right steps for your soldering iron can make your life easier.

By following the given tips, you can protect your soldering iron tip from damage, reduce wear and tear, and extend its lifespan.

Other useful posts: